Rabman

Active Member

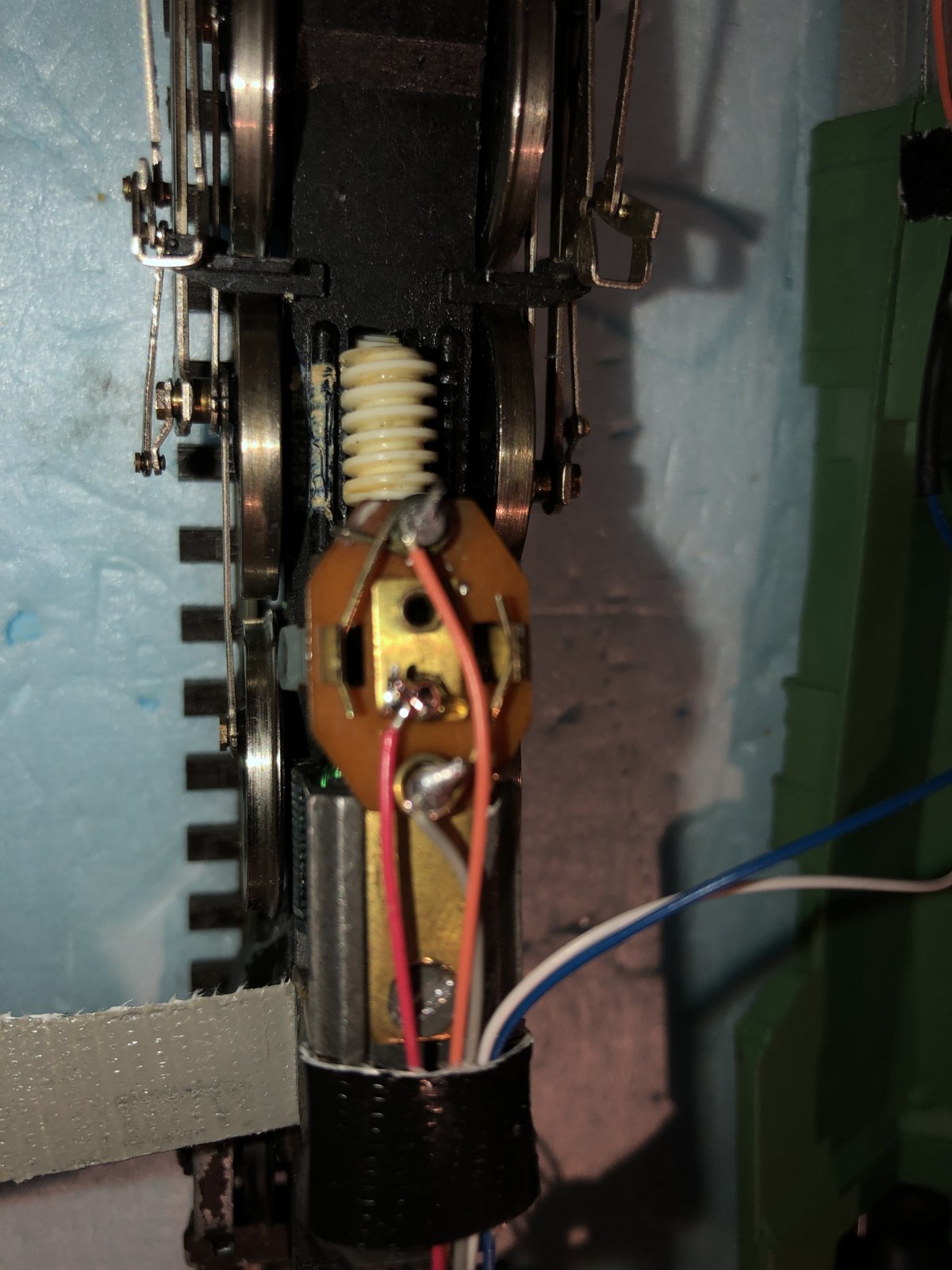

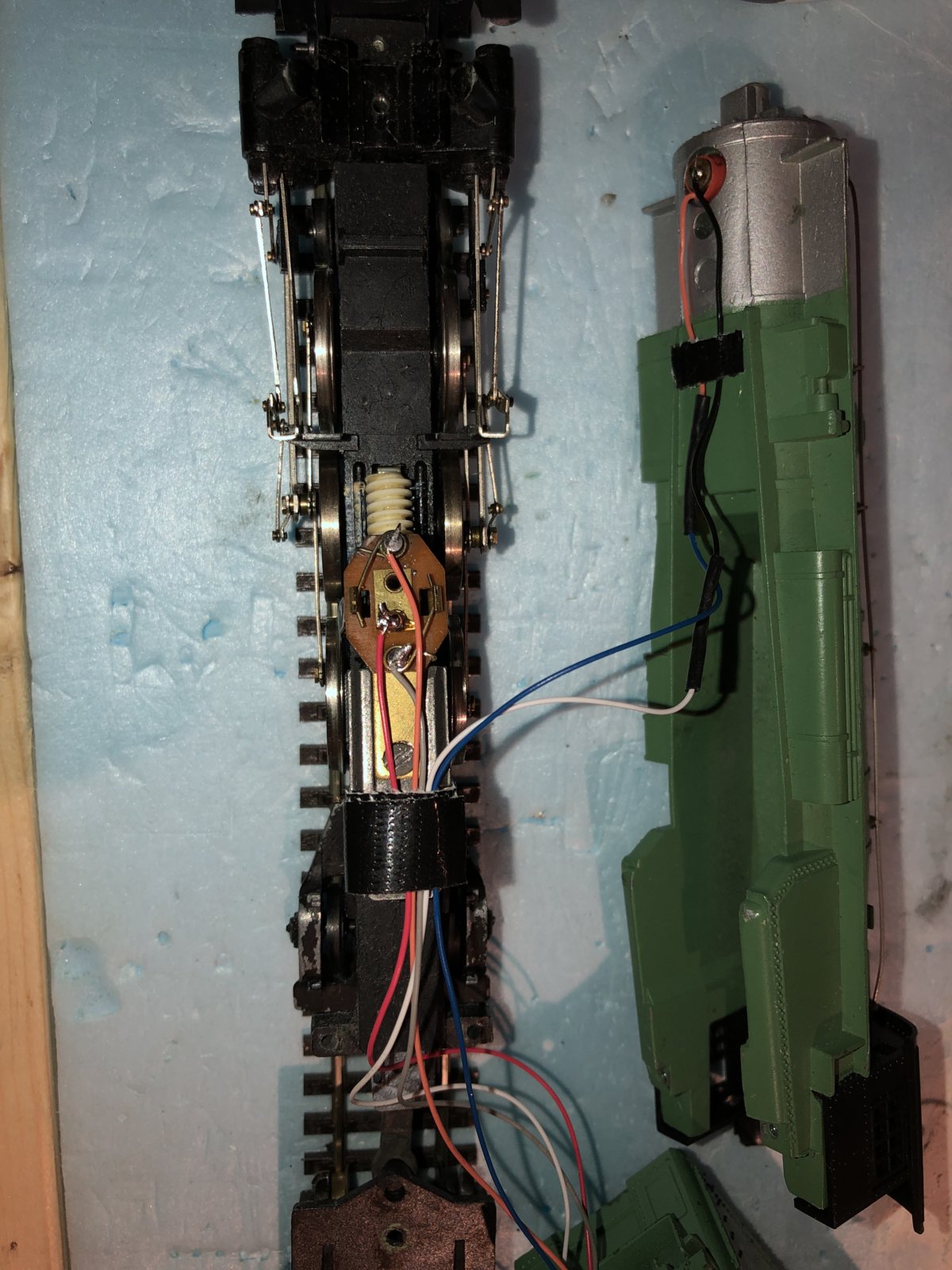

So I installed a Digitrax DH-123D Decoder in my green 4-6-2 locomotive.

Isolating the motor was fairly easy. I pulled out the spring pivot point, cut the brass conductor bracket, and the reinstalled the pivot point for the brush.

I picked up the track power where the red wire is from the brass bracket I cut. The black wire track power is coming from the tenders bottom frame.

Grey and orange wires to the commutator brush spring pivot pins. I do need to reverse the two wires to get the direction right. I am aware it can also be done by setting a CV value.

I did connect the headlight to the blue and white wires of the Decoder.

I cleaned the tenders wheels as the brass was quite dirty. I have some more cleaning to do as they are not sparkling. Also I did not clean out the area between the axle and truck. I cleaned the locomotive wheels also a bit, though they didn’t look too bad. More wheel cleaning to do. One pain is the tenders wheels cannot be removed as the bottom casting on the bolsters are peened on, not bolted.

So I suspect I have a power quality issue for a number of reasons.

1) at best the locomotive will crawl erratically.

2) making a humming noise when track power is turned on with zero throttle.

3) need to replace the headlight, it isn’t working. Perhaps I blew the bulb when I soldered a wire to the threaded portion. I do have an LED I can replace it with.

So my action plan is:

1) Get a jumper wire with alligator clips and connect to the rail the tender picks power from to the black wire of the Decoder. See if it’s a tender wheel connection issue.

2) repeat the process with the red wire to connect it to the other rail to see if that’s the issue.

3) pull the motor off the frame to see if it behaves properly.

4) all else fails, modify the motor I received with my mikado 2-8-2 to see if it behaves better. I also have new trucks and wheels for the tender to see if that makes the situation better.

5) disconnect the headlight bulb to reduce power draw.

So I am aware these are forty year old plus motors, maybe the power draw is just too much for the Decoder. I tried measuring the current draw of the motor but my meter only goes to 300mA and it is much more than that I’m sure.

A few points: the locomotive with the motor removed seems to be fairly smooth rolling. The tender does make some rough rolling sounds.

When the loco was hooked up to dc, it didn’t start moving until I put about 60% power to it. This predated my wheel cleaning though. The motor turns freely and smoothly when removed from the locomotive. Spins quite fast. I cleaned up the commutator brushes and plus the axles and pivots of the linkages.

A few questions:

Do you think these are good steps to debug?

Am I missing anything?

Is this ever going to work?

Any idea what the issues could be? As mentioned I suspect it is power or an old motor. Blown headlight bulb.

Isolating the motor was fairly easy. I pulled out the spring pivot point, cut the brass conductor bracket, and the reinstalled the pivot point for the brush.

I picked up the track power where the red wire is from the brass bracket I cut. The black wire track power is coming from the tenders bottom frame.

Grey and orange wires to the commutator brush spring pivot pins. I do need to reverse the two wires to get the direction right. I am aware it can also be done by setting a CV value.

I did connect the headlight to the blue and white wires of the Decoder.

I cleaned the tenders wheels as the brass was quite dirty. I have some more cleaning to do as they are not sparkling. Also I did not clean out the area between the axle and truck. I cleaned the locomotive wheels also a bit, though they didn’t look too bad. More wheel cleaning to do. One pain is the tenders wheels cannot be removed as the bottom casting on the bolsters are peened on, not bolted.

So I suspect I have a power quality issue for a number of reasons.

1) at best the locomotive will crawl erratically.

2) making a humming noise when track power is turned on with zero throttle.

3) need to replace the headlight, it isn’t working. Perhaps I blew the bulb when I soldered a wire to the threaded portion. I do have an LED I can replace it with.

So my action plan is:

1) Get a jumper wire with alligator clips and connect to the rail the tender picks power from to the black wire of the Decoder. See if it’s a tender wheel connection issue.

2) repeat the process with the red wire to connect it to the other rail to see if that’s the issue.

3) pull the motor off the frame to see if it behaves properly.

4) all else fails, modify the motor I received with my mikado 2-8-2 to see if it behaves better. I also have new trucks and wheels for the tender to see if that makes the situation better.

5) disconnect the headlight bulb to reduce power draw.

So I am aware these are forty year old plus motors, maybe the power draw is just too much for the Decoder. I tried measuring the current draw of the motor but my meter only goes to 300mA and it is much more than that I’m sure.

A few points: the locomotive with the motor removed seems to be fairly smooth rolling. The tender does make some rough rolling sounds.

When the loco was hooked up to dc, it didn’t start moving until I put about 60% power to it. This predated my wheel cleaning though. The motor turns freely and smoothly when removed from the locomotive. Spins quite fast. I cleaned up the commutator brushes and plus the axles and pivots of the linkages.

A few questions:

Do you think these are good steps to debug?

Am I missing anything?

Is this ever going to work?

Any idea what the issues could be? As mentioned I suspect it is power or an old motor. Blown headlight bulb.

Last edited: