flyboy2610

Loveably weird

A couple of weeks ago, I purchased a Rivarossi observation car in UP greyhound scheme. I've been collecting cars in this color scheme for a passenger train. I like the look of these cars a lot better than the normal UP Armour yellow and gray scheme. I have a UP 4-8-4, #806, that I installed a Soundtraxx Tsunami sound decoder in. It will look smart at the head of this train!

I bought this car to finish off the tail of the train. I'd been looking for a greyhound scheme observation car, and when I saw this I snapped it up. The windows are dirty and don't want to come clean. Sometime in its lifetime someone touched the windows with smudgy fingers and now I can't get them clean. I'll keep trying, though! On these cars, the roof and windows are glued together at the factory. There are 6 tabs (two of which are broken on this car) which snap into slots in the floor to hold the roof/windows on.

The car came with truck mounted horn hook couplers. Truck mounted couplers on a long car like this don't bother me to much. This will be the last car of the train, and I do not have to back into the passenger station. The other 5 cars in the train are Walthers Heavyweight cars with body mounted couplers. The curves on the mainline are all 24" radius or greater.

This car was also a real lightweight, and I'm talking literally here! It is 11-1/4" long, so according to NMRA recommendations it should weigh 6.6 ounces. It weighed 4. I used 1-1/2 ounces of weight over each truck to bring it up to 7 ounces. A bit over, but there are no grades on my layout, so it should be fine. It also had 33" wheels instead of the 36" wheels you would normally expect to find on a heavyweight passenger car. More on this later. I removed the stock wheels, and will be replacing them with Proto 2000 36" metal wheels. A test fit reveals that they roll very smoothly in the trucks.

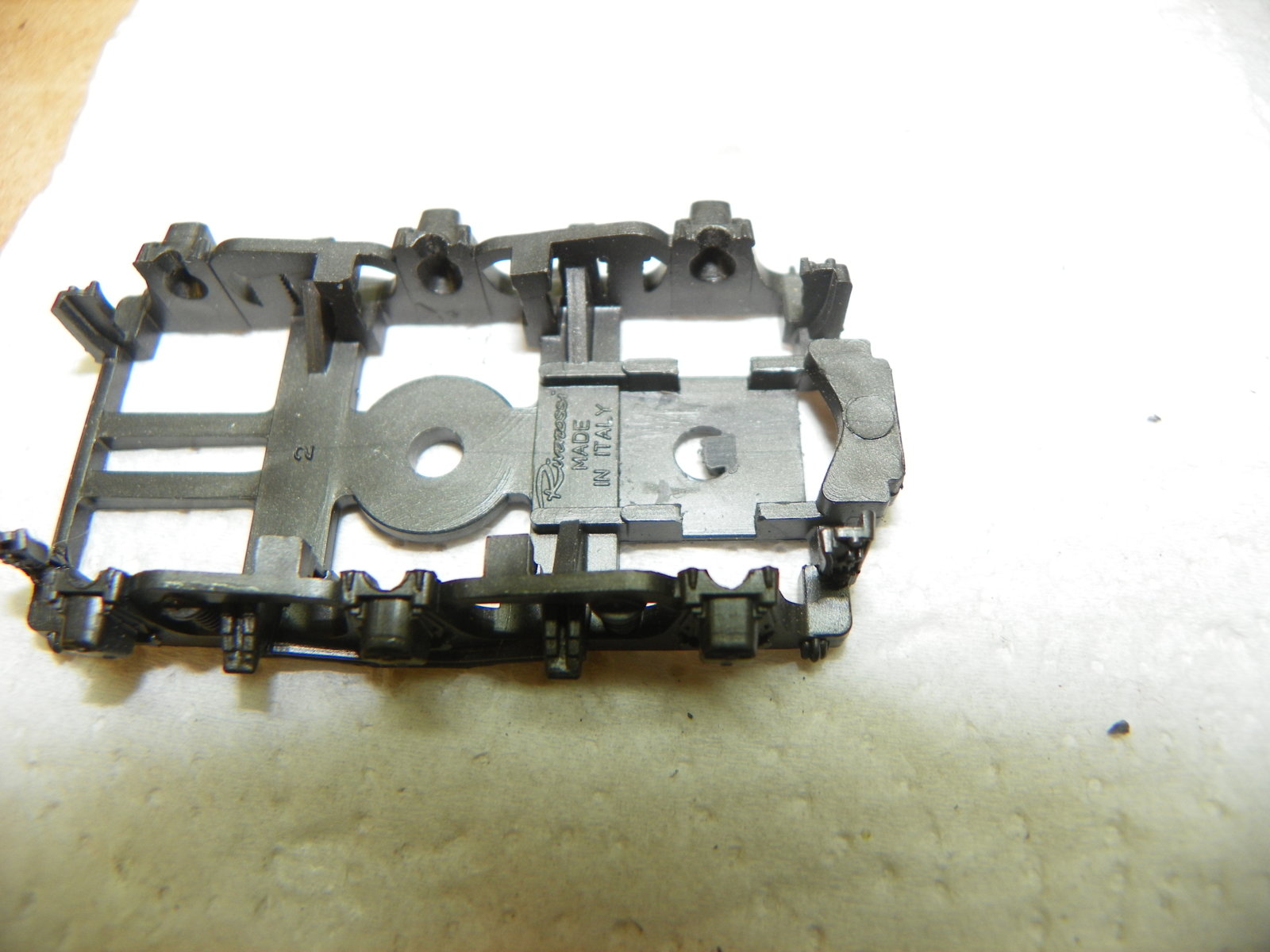

Here's a pic of the car in it's state of disassembly:

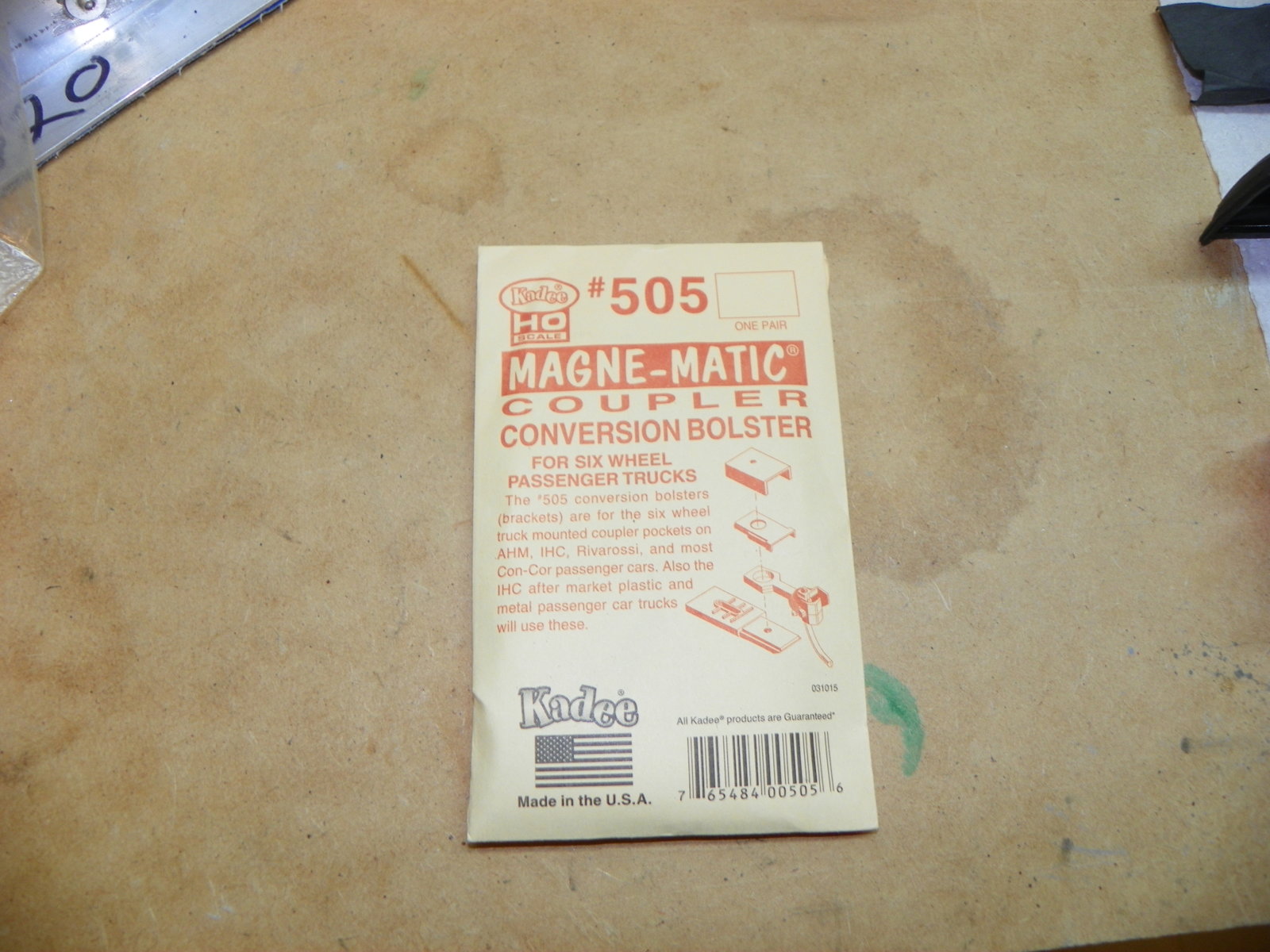

I checked Kadee's website, and the conversion requires a #505 bolster for each truck. Last Saturday I placed an order with M.B. Klein's. It shipped Tuesday morning, I had the package Thursday evening. These are the bolsters required:

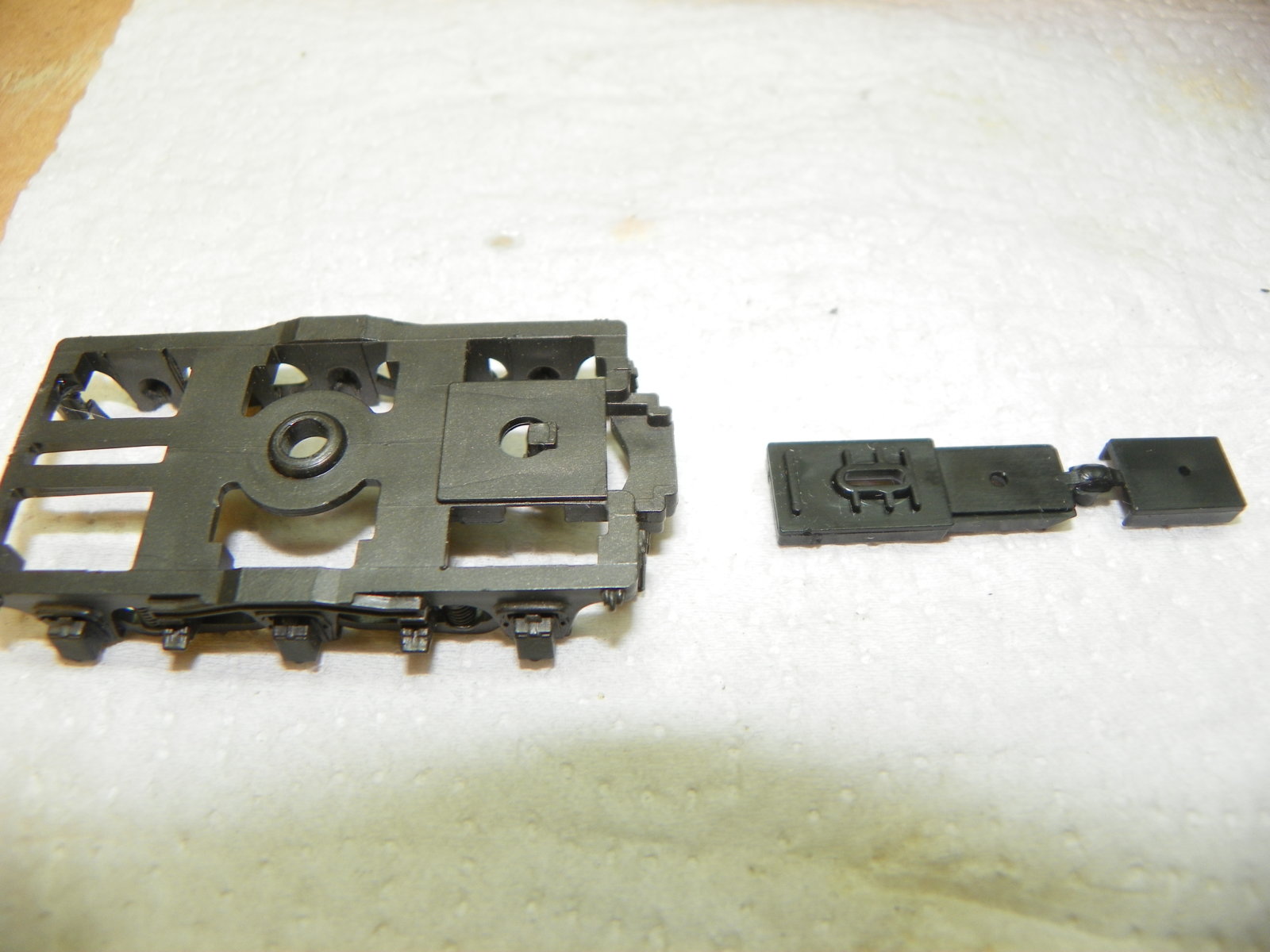

This is what comes in the package: two each bolsters, #5 couplers and centering springs, two short self tapping screws, two long self tapping screws, and a few extra knuckle springs. You also get instructions, but we never look at those do we? In this case, you'd better!

In the previous pic, I have one bolster facing up and one facing down so you can see the details. The bolster is slotted to permit back and forth adjustment of the coupler. You can see the slot in the top bolster. On the bottom bolster, you will see a series of raised lines on the sides and ends of the slot. Whether or not you keep those depends on which car you have. The early AHM cars came with 33" wheels. Mine had 33" wheels, so I have an early car. The later cars came with the correct 36" wheels.

The original 33" plastic wheels is on the left, the replacement Proto 2000 36" wheel is on the right.

The spacer lines on the bolster are there to set the proper coupler height. If the 33" wheels are replaced with 36" wheels, the coupler will then sit too high. The spacers lines lower the coupler back down to the proper height. If the original 33" wheels are retained, the spacer lines must be filed off or the coupler will sit too low.

So: If you have a later car with 36" wheels from the factory, the truck has been manufactured to place the coupler at the proper height. Leaving the spacers on will result in the coupler being to low. The spacers must be removed.

If you have an early car with 33" wheels, the truck has been manufactured to place the coupler at the proper height. Leaving the spacers on will result in the coupler being to low. The spacers must be removed only if the 33" wheels are retained!

The only time the spacers must be retained is if you have an early car with 33" wheels and you replaced them with 36" wheels. Removing the spacers will result in the coupler being too high. I have an early car with 33" wheels, and they will be replaced with 36" wheels, therefore I need to retain the spacers. That should save a lot of filing, right? Guess again!

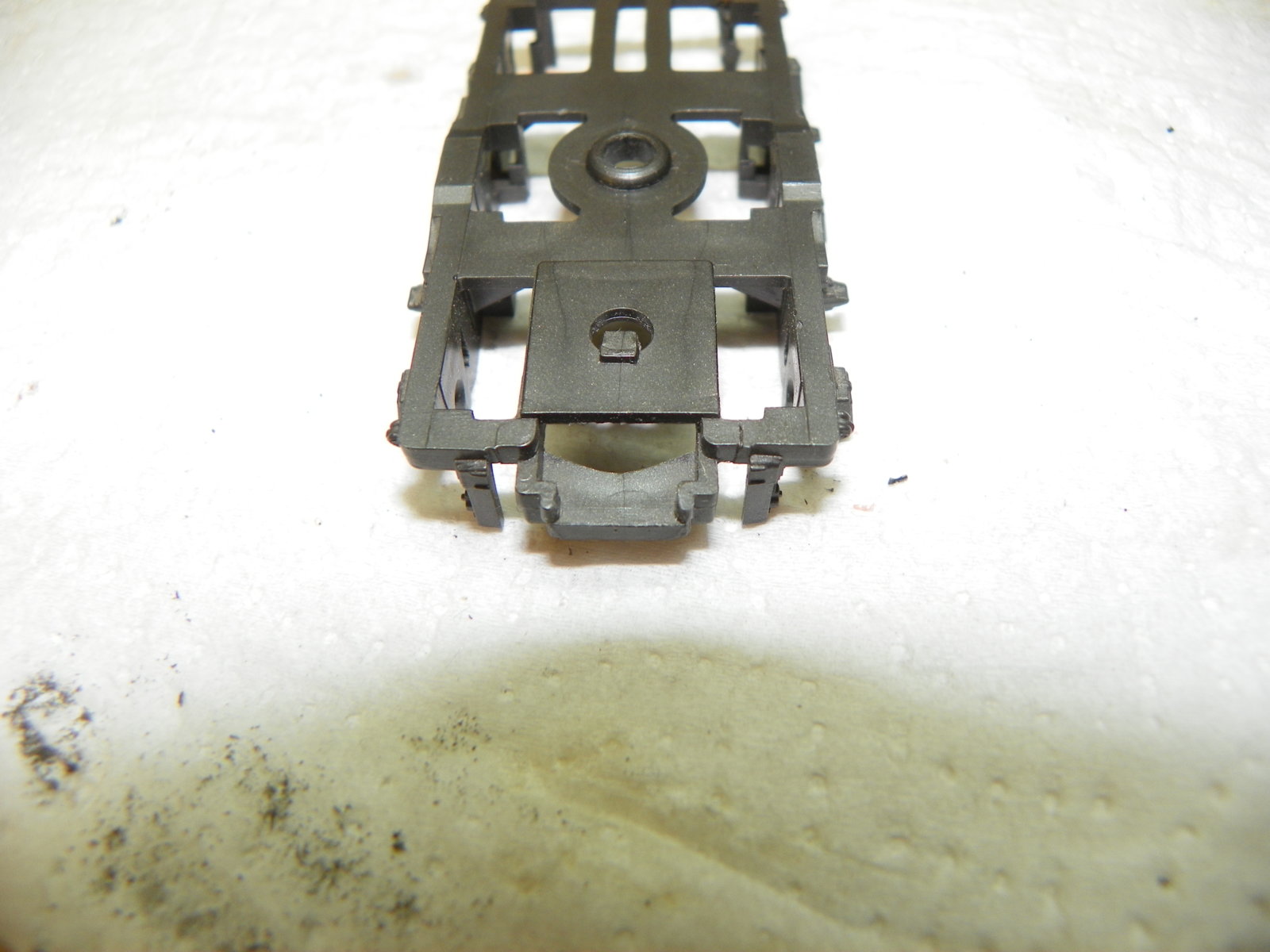

The pin that the old horn hook coupler clipped onto must be cut off and filed down smooth with the top of the plate.

The bar across the front has two sides with small L-shaped ledges that must also be removed. These have to be removed so the bolster can slide into the pocket.

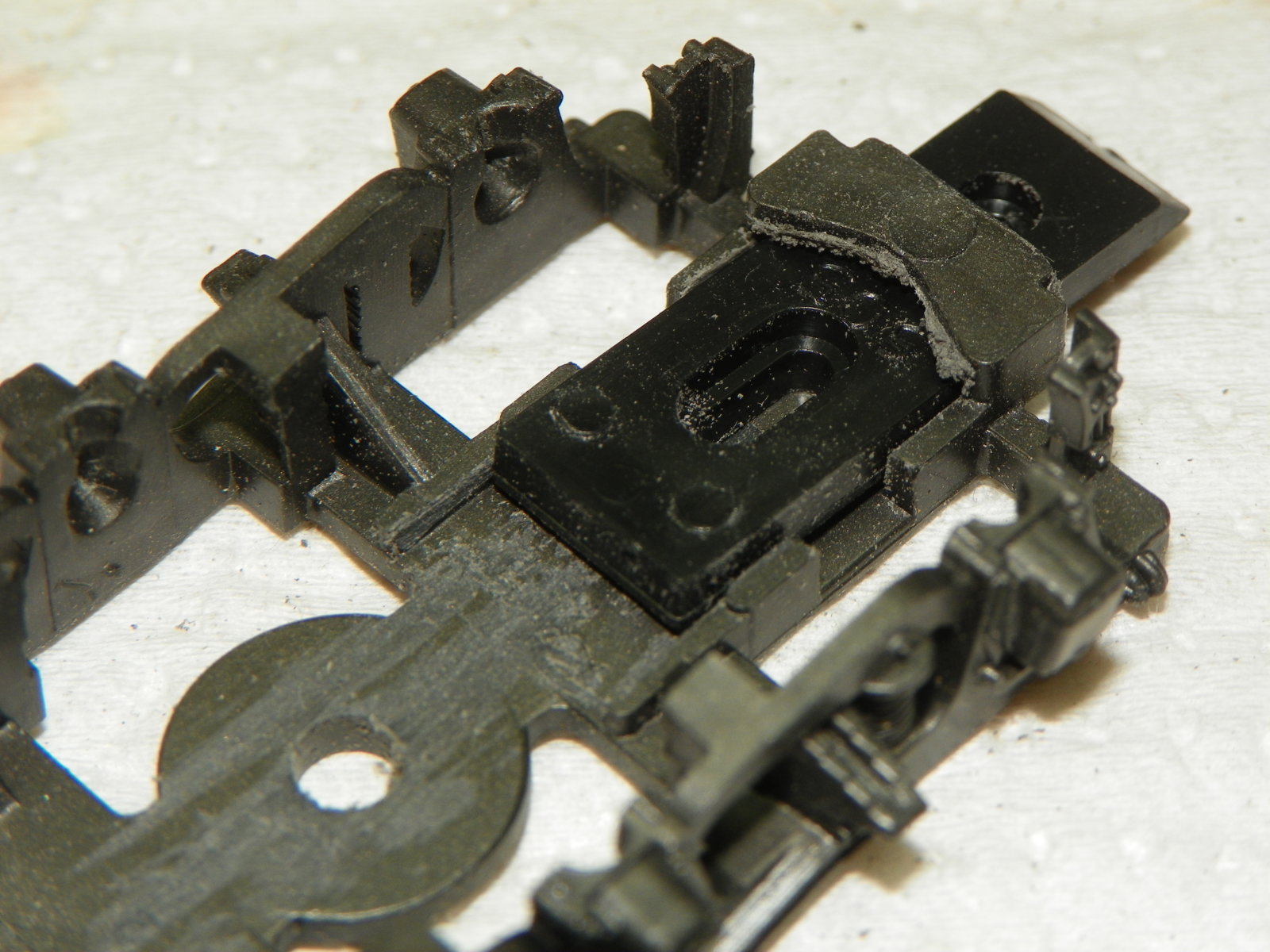

The instructions say to remove the center bar if using the spacers on the bolster. Otherwise the bolster will be too thick to slide into the pocket. They also say do not remove the bar unless absolutely necessary because doing so will weaken the pocket and eliminate a potential mounting point for the bolster. I chose to leave the bar in place, but file it down thin enough to still be able to slide the bolster into the pocket. It's not laser level flat, but it will do:

A couple pics of how the bolster slides into the pocket.

The instructions say to assemble the coupler onto the bolster before fitting the bolster onto the truck. I chose to leave the coupler off until I was done fitting the bolster. I felt there was less chance of damaging the coupler that way. I'll continue this in my next post. I can't post any more pics to this one.

I bought this car to finish off the tail of the train. I'd been looking for a greyhound scheme observation car, and when I saw this I snapped it up. The windows are dirty and don't want to come clean. Sometime in its lifetime someone touched the windows with smudgy fingers and now I can't get them clean. I'll keep trying, though! On these cars, the roof and windows are glued together at the factory. There are 6 tabs (two of which are broken on this car) which snap into slots in the floor to hold the roof/windows on.

The car came with truck mounted horn hook couplers. Truck mounted couplers on a long car like this don't bother me to much. This will be the last car of the train, and I do not have to back into the passenger station. The other 5 cars in the train are Walthers Heavyweight cars with body mounted couplers. The curves on the mainline are all 24" radius or greater.

This car was also a real lightweight, and I'm talking literally here! It is 11-1/4" long, so according to NMRA recommendations it should weigh 6.6 ounces. It weighed 4. I used 1-1/2 ounces of weight over each truck to bring it up to 7 ounces. A bit over, but there are no grades on my layout, so it should be fine. It also had 33" wheels instead of the 36" wheels you would normally expect to find on a heavyweight passenger car. More on this later. I removed the stock wheels, and will be replacing them with Proto 2000 36" metal wheels. A test fit reveals that they roll very smoothly in the trucks.

Here's a pic of the car in it's state of disassembly:

I checked Kadee's website, and the conversion requires a #505 bolster for each truck. Last Saturday I placed an order with M.B. Klein's. It shipped Tuesday morning, I had the package Thursday evening. These are the bolsters required:

This is what comes in the package: two each bolsters, #5 couplers and centering springs, two short self tapping screws, two long self tapping screws, and a few extra knuckle springs. You also get instructions, but we never look at those do we? In this case, you'd better!

In the previous pic, I have one bolster facing up and one facing down so you can see the details. The bolster is slotted to permit back and forth adjustment of the coupler. You can see the slot in the top bolster. On the bottom bolster, you will see a series of raised lines on the sides and ends of the slot. Whether or not you keep those depends on which car you have. The early AHM cars came with 33" wheels. Mine had 33" wheels, so I have an early car. The later cars came with the correct 36" wheels.

The original 33" plastic wheels is on the left, the replacement Proto 2000 36" wheel is on the right.

The spacer lines on the bolster are there to set the proper coupler height. If the 33" wheels are replaced with 36" wheels, the coupler will then sit too high. The spacers lines lower the coupler back down to the proper height. If the original 33" wheels are retained, the spacer lines must be filed off or the coupler will sit too low.

So: If you have a later car with 36" wheels from the factory, the truck has been manufactured to place the coupler at the proper height. Leaving the spacers on will result in the coupler being to low. The spacers must be removed.

If you have an early car with 33" wheels, the truck has been manufactured to place the coupler at the proper height. Leaving the spacers on will result in the coupler being to low. The spacers must be removed only if the 33" wheels are retained!

The only time the spacers must be retained is if you have an early car with 33" wheels and you replaced them with 36" wheels. Removing the spacers will result in the coupler being too high. I have an early car with 33" wheels, and they will be replaced with 36" wheels, therefore I need to retain the spacers. That should save a lot of filing, right? Guess again!

The pin that the old horn hook coupler clipped onto must be cut off and filed down smooth with the top of the plate.

The bar across the front has two sides with small L-shaped ledges that must also be removed. These have to be removed so the bolster can slide into the pocket.

The instructions say to remove the center bar if using the spacers on the bolster. Otherwise the bolster will be too thick to slide into the pocket. They also say do not remove the bar unless absolutely necessary because doing so will weaken the pocket and eliminate a potential mounting point for the bolster. I chose to leave the bar in place, but file it down thin enough to still be able to slide the bolster into the pocket. It's not laser level flat, but it will do:

A couple pics of how the bolster slides into the pocket.

The instructions say to assemble the coupler onto the bolster before fitting the bolster onto the truck. I chose to leave the coupler off until I was done fitting the bolster. I felt there was less chance of damaging the coupler that way. I'll continue this in my next post. I can't post any more pics to this one.