Hi all, have been busy this past week or so so apologies for the delayed replies.

Amtrakking,

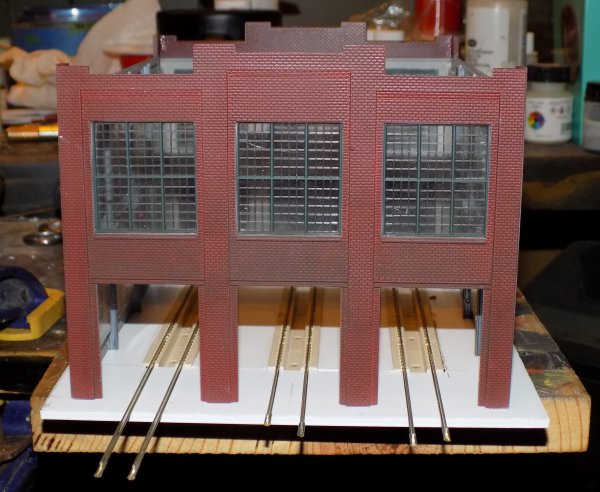

Yep I think they look great when assembled and can (probably) be used for a lot of purposes.

Sherrel:

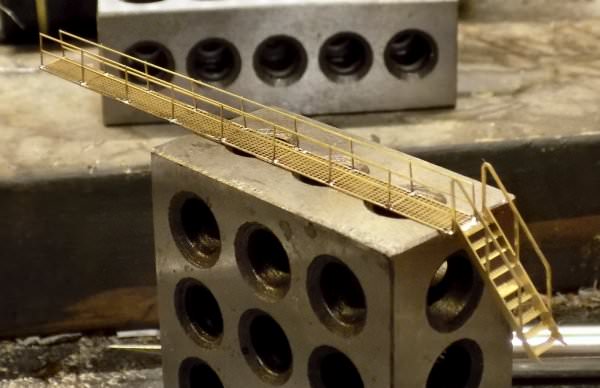

The length of one section of walkway is 3.5"

The width of each walkway is 1/4"

The hieght of the railings is 1/4"

The steps are also 1/4" wide and high with railings and raise the walkway 5/8"

The steps are one piece and everything (railings and treads) fold up or out to suit using tweezers. The walkway comes in two parts, the walkway itself and the railings that fit into pre drilled holes in the walkway.

The walkways and railings can be joined, or cut, for longer or shorter lengths as well. I will possibly remove a part of one of the railings to allow for access to the engines. These "kits" are very flexible and very well made. While I was a little cautious about their fragility, I was surprised to find just how robust they are.