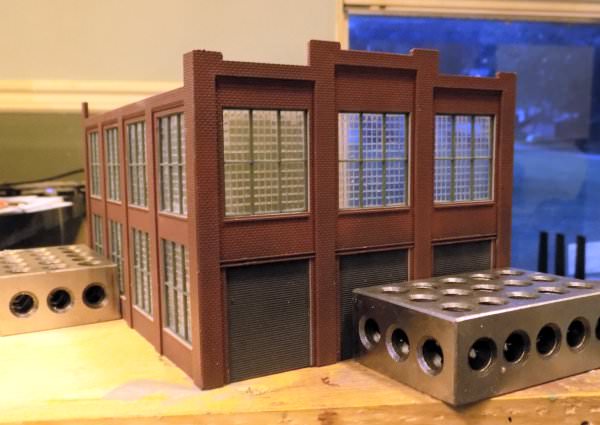

I'm a little bit late to the party, and I didn't see it explicitly stated unless I skimmed over it, but looks like you're actually building it as a locomotive heavy shop? Despite the "car shop" label on the box, it can work quite well for this as well and should turn out great.

The inspection pits and walkway-level platforms are right at home in a loco repair shop, while a car shop wouldn't need any of this. I've toured one, and the floors are just solid concrete, no pits or walkways. The interior detailing for a car shop would mostly consist of moveable "stuff" like welders, car jacks, stepladders and other tools etc.