Believe it or not, but I have seen much worse. For first timers - and considering the tribulations of the material, I think a few of them look - shall we say - passable?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

The Louisville Railroad

- Thread starter Iron Horseman

- Start date

Iron Horseman

Well-Known Member

After the session, one woman went out and found "how to build trees" on the web. She found the "twist your own" type. I told her that I had built trees like that as well, but didn't think we had the time. I brought in the supplies so she could try it. I believe she has made one tree since then. "The web made it look so easy.", was the reply.

Last edited:

goscrewyourselves

I'm the one

Horseman,

At least she was keen enough to look the info up ... who knows, you may have created a "Tree Master"

At least she was keen enough to look the info up ... who knows, you may have created a "Tree Master"

Iron Horseman

Well-Known Member

Dateline April 3.

The boss comes into the office and looks over all the train stuff piled on the table. He is concerned there is no Union Pacific box car, and no locomotive painted for our company. So this of course causes a panic rush back to the on-line retailers to find some UP equipment. All stuff with "Building America" logos seems to be sold out or not delivered yet. By chance I went to the Caboose site and even though the Atlas site showed their 65" Trinity reefers were not yet delivered, Cabooses's site showed they were "in stock". "How odd", I thought as I picked up the phone and called Caboose. The fellow who answered went to the shelf and sure enough they were there.

So I placed two more orders for equipment and supplies one with Caboose and another directly to Walthers. Got the new "Building America" reefer from Caboose as well as some bridge abutments and scenic elements. For some reason I decided to go with a pretty elaborate bridge arrangement on the back bridge - 30' deck, 70' through truss, and another 30' deck. Walther's and their bridge system supplied the materials and directions. Also ordered the paint for the company logo'ed locomotive.

So now I can tell the president his UP cars and loco are on the way.

The boss comes into the office and looks over all the train stuff piled on the table. He is concerned there is no Union Pacific box car, and no locomotive painted for our company. So this of course causes a panic rush back to the on-line retailers to find some UP equipment. All stuff with "Building America" logos seems to be sold out or not delivered yet. By chance I went to the Caboose site and even though the Atlas site showed their 65" Trinity reefers were not yet delivered, Cabooses's site showed they were "in stock". "How odd", I thought as I picked up the phone and called Caboose. The fellow who answered went to the shelf and sure enough they were there.

So I placed two more orders for equipment and supplies one with Caboose and another directly to Walthers. Got the new "Building America" reefer from Caboose as well as some bridge abutments and scenic elements. For some reason I decided to go with a pretty elaborate bridge arrangement on the back bridge - 30' deck, 70' through truss, and another 30' deck. Walther's and their bridge system supplied the materials and directions. Also ordered the paint for the company logo'ed locomotive.

So now I can tell the president his UP cars and loco are on the way.

goscrewyourselves

I'm the one

Looking forward to seeing pictures of this, your bridge sounds as though it is going to be a focal point of the layout. Oh and yep, gotta keep the Boss happy

Iron Horseman

Well-Known Member

So one of my posts has vanished into the electronic aether.

Rewinding a bit, Dateline March 29

Friday March 30th is a holiday at our company. So I stayed late Thursday, spent all day Friday, and all day Saturday working on the sub-roadbed. One can measure and plan as long as they want but eventually one has to put the blade to the wood. The really bad part was that before the wood had been cut outside and the unit was assembled this by the garage door. But now I am working "in place" meaning all this sawdust is going straight into the carpet. I spent 2 hours cleaning up Friday and Saturday night with the pathetic little vacuum our office owns. What a waste of time that was.

Once again the odd shape of the space made it difficult. Everything had to be measured from the rear and right side of the area. I also decided to just use a large expanse of plywood for the intermodal yard, and add an additional short spur at the front.

I ended up adding a couple more supports in the process. In the end it came out well, I think I could walk on all of it except where the trestle will be in the front (which in the photo below is the far top left.

Rewinding a bit, Dateline March 29

Friday March 30th is a holiday at our company. So I stayed late Thursday, spent all day Friday, and all day Saturday working on the sub-roadbed. One can measure and plan as long as they want but eventually one has to put the blade to the wood. The really bad part was that before the wood had been cut outside and the unit was assembled this by the garage door. But now I am working "in place" meaning all this sawdust is going straight into the carpet. I spent 2 hours cleaning up Friday and Saturday night with the pathetic little vacuum our office owns. What a waste of time that was.

Once again the odd shape of the space made it difficult. Everything had to be measured from the rear and right side of the area. I also decided to just use a large expanse of plywood for the intermodal yard, and add an additional short spur at the front.

I ended up adding a couple more supports in the process. In the end it came out well, I think I could walk on all of it except where the trestle will be in the front (which in the photo below is the far top left.

Last edited:

goscrewyourselves

I'm the one

It seems to have mate ... all there was was an empty box that seemed to have been posted. There has been a few times that has happened so it isn't just you.So one of my posts has vanished into the electronic either.

I think the "odd shape" gives it a lot of character though. It is looking very good!

Iron Horseman

Well-Known Member

Date Line - Tuesday Night April 3rd

I took Monday night off, but was back at it Tuesday after work. I took one of the Masonite boards we had broken and put it in the shower to soak. After about 30 minutes, flipping every 5 minutes or so, I bent it into the corner and clamped it in place to dry. Between flips I began working on the foam inserts.

Date Line April 4th.

Began farming out the structures to the volunteers. I didn't realize everyone doesn't own a hobby knife or small paint brushes. Had to go to Hobby Lobby and buy a bunch, as well as more styrene cement bottles. It wasn't going to work if we all had to share one.

Date Line April 5th.

Worked on the backdrop some more measuring and assembling pieces. Fit more foam. Started building the mine building.

Date Line April 6th.

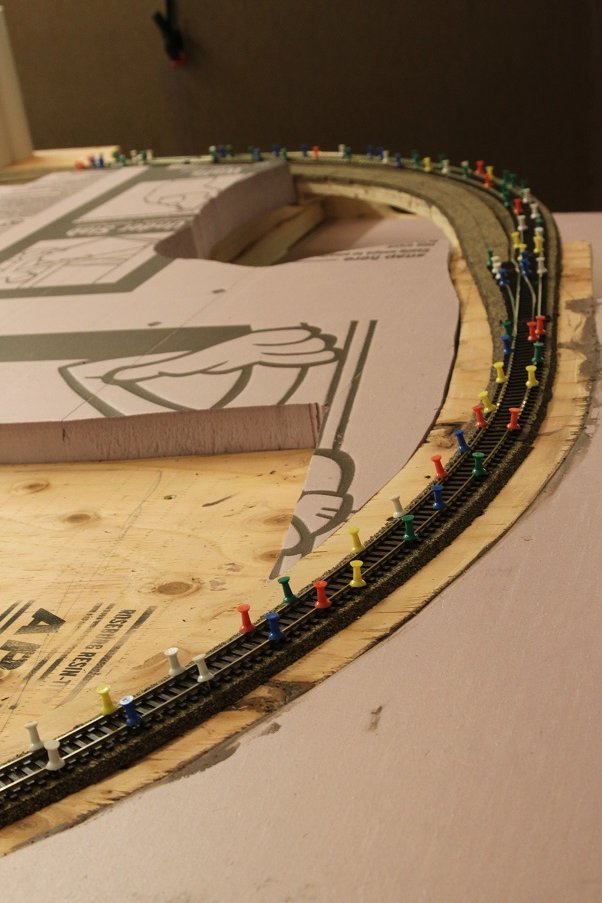

Beginning the weekend I had a goal to get the backdrop done and roadbed in. So Friday night I did the sub-roadbed under the bridges and started putting in the cork. Time just flew by and I only had a few pieces inbefore it was time to go home. I had three people show up on Saturday to help. I showed one fellow how to put the cork in, and another one how to bend the Masonite. By this time I was to the point of saying, "Normally I would do this but since we are out of time..." In this case it was the nails in the cork. Normally I would wait for the adhesive to dry and then go back and pull them out.

While the others were working on their tasks, I worked on putting in the foam. This was because the foam is something I was making up on the fly, and could not tell anyone else how to do it. Everyone else left by 4:00 but I continued on until 10 or so. I had about 1/2 inch of foam dust all over the floor that it took over an hour to clean up.

Sunday I finished the cork roadbed, did the sub-roadbed for the mine and the other "unknown" industry at the lower right, and went back to foam. The plan is for the trackage to go directly onto the sub-roadbed for the mine and the inter-modal yard

I took Monday night off, but was back at it Tuesday after work. I took one of the Masonite boards we had broken and put it in the shower to soak. After about 30 minutes, flipping every 5 minutes or so, I bent it into the corner and clamped it in place to dry. Between flips I began working on the foam inserts.

Date Line April 4th.

Began farming out the structures to the volunteers. I didn't realize everyone doesn't own a hobby knife or small paint brushes. Had to go to Hobby Lobby and buy a bunch, as well as more styrene cement bottles. It wasn't going to work if we all had to share one.

Date Line April 5th.

Worked on the backdrop some more measuring and assembling pieces. Fit more foam. Started building the mine building.

Date Line April 6th.

Beginning the weekend I had a goal to get the backdrop done and roadbed in. So Friday night I did the sub-roadbed under the bridges and started putting in the cork. Time just flew by and I only had a few pieces inbefore it was time to go home. I had three people show up on Saturday to help. I showed one fellow how to put the cork in, and another one how to bend the Masonite. By this time I was to the point of saying, "Normally I would do this but since we are out of time..." In this case it was the nails in the cork. Normally I would wait for the adhesive to dry and then go back and pull them out.

While the others were working on their tasks, I worked on putting in the foam. This was because the foam is something I was making up on the fly, and could not tell anyone else how to do it. Everyone else left by 4:00 but I continued on until 10 or so. I had about 1/2 inch of foam dust all over the floor that it took over an hour to clean up.

Sunday I finished the cork roadbed, did the sub-roadbed for the mine and the other "unknown" industry at the lower right, and went back to foam. The plan is for the trackage to go directly onto the sub-roadbed for the mine and the inter-modal yard

Last edited:

goscrewyourselves

I'm the one

Horseman,

Your making terrific progress and it is looking very VERY good. Can't wait to see the first train/engine rolling around it

Your making terrific progress and it is looking very VERY good. Can't wait to see the first train/engine rolling around it

Iron Horseman

Well-Known Member

You might notice a funny little wiggle in the road bed in that second picture. I was very specific to the fellow putting it in, that I needed that wiggle to make the turnouts to the mine align properly. A few days later, after he worked so hard to get it that way, for scenery reasons I had to realign anyway with a straight piece of track there. I fixed the tight curve issue by cutting a piece of pre-molded sectional track

Iron Horseman

Well-Known Member

Dateline April 9 - Monday

Got out the sander and sanded all the humps and bumps off the roadbed. Was really tempted to pull all the nails but decided there was just not time to do that.

Dateline April 10 - Tuesday

Really getting down to the wire so I stayed late after work and began laying track. Since I was in a hurry I immediately began to make mistakes. First was, oh yeah, the Peco turnouts don't allow for the length of ties on the connecting track. I knew that but it bit me at least three times. Got the adhesive on the rail and try to connect it to the turnout and ties bump. It is so annoying trying to cut ties down when there is already sticky goop all over the back side of them. Even more annoying is that this makes it easy to cut them too short. As is obvious in the photo below.

Got out the sander and sanded all the humps and bumps off the roadbed. Was really tempted to pull all the nails but decided there was just not time to do that.

Dateline April 10 - Tuesday

Really getting down to the wire so I stayed late after work and began laying track. Since I was in a hurry I immediately began to make mistakes. First was, oh yeah, the Peco turnouts don't allow for the length of ties on the connecting track. I knew that but it bit me at least three times. Got the adhesive on the rail and try to connect it to the turnout and ties bump. It is so annoying trying to cut ties down when there is already sticky goop all over the back side of them. Even more annoying is that this makes it easy to cut them too short. As is obvious in the photo below.

Last edited:

Iron Horseman

Well-Known Member

Second mistake was that coming off the turnout with rails flush, I forgot to shorten the outside rail. At 28" radius at the end of 3' of flex, there was still not enough offset to make a good transition to the next piece of flex track. There was only an inch or so. Since I already had goop all over the back of the track I left it. Sure enough the ties in this section couldn't hold and I got two kinks, one in each rail. Fortunately it was easy enough to fix by adding two very large wire nail "spikes".

This photo also shows a couple of other things. This is the first time I've used latex caulk for adhesive. the rail on the left I put the goop on the back of the rail. On the right I spread the goop on the roadbed and just sat the rail on top. Normally I use matte medium. Matte medium is clear, this stuff looks like a mess. I know eventually ballast will cover it, but in the mean time - yuck. Since I knew there would not be time for ballast, after this section of track I went back to the caulk on the back and cleaned up the surplus between laying each section. It looks much better. In my opinion this is still a horrible mess (caulk & track) that I would have totally taken out and done again where the time constraints not there.

I will say the latex caulk dries or at least sets up much quicker than the matte. There was even some holding power there while I positioned the track into its final place.

This photo also shows a couple of other things. This is the first time I've used latex caulk for adhesive. the rail on the left I put the goop on the back of the rail. On the right I spread the goop on the roadbed and just sat the rail on top. Normally I use matte medium. Matte medium is clear, this stuff looks like a mess. I know eventually ballast will cover it, but in the mean time - yuck. Since I knew there would not be time for ballast, after this section of track I went back to the caulk on the back and cleaned up the surplus between laying each section. It looks much better. In my opinion this is still a horrible mess (caulk & track) that I would have totally taken out and done again where the time constraints not there.

I will say the latex caulk dries or at least sets up much quicker than the matte. There was even some holding power there while I positioned the track into its final place.

Last edited:

Iron Horseman

Well-Known Member

Dateline April 11 - Wednesday

Pulled the pins and added the next sections of track as far as the pins would go. The foam is worth noting. I found it was nice to lay the whole sheet of foam over the roadbed and then use a permanent marker to draw along the edges. Flip the foam and cut along the line. In that manner I was able to cut this whole piece to the left in one "fitting". It dropped right into place.

The brown in the background is the masonite for the backdrop. I figured out a way to splice 4 pieces together into the oval shape. The clamp is holding one of the overlapping pieces (tounge and grove style) that is being glued to the main structure.

Pulled the pins and added the next sections of track as far as the pins would go. The foam is worth noting. I found it was nice to lay the whole sheet of foam over the roadbed and then use a permanent marker to draw along the edges. Flip the foam and cut along the line. In that manner I was able to cut this whole piece to the left in one "fitting". It dropped right into place.

The brown in the background is the masonite for the backdrop. I figured out a way to splice 4 pieces together into the oval shape. The clamp is holding one of the overlapping pieces (tounge and grove style) that is being glued to the main structure.

goscrewyourselves

I'm the one

Looking good Horseman and you are making good progress and I am picking up some great points from watching the build.

Iron Horseman

Well-Known Member

Dateline April 12 - Thursday (one week to show time)

My birthday, I'm officially an old man now, spent it after work putting in the next section of rail and next section of the back drop. After I got home I worked on the mine building knowing I had to have enough of it done to get the tracks positioned properly.

Dateline April 13 - Friday

Repeat of previous days, next section of track as far as the pins would go, next section of back drop done. Now getting close to the bridges I put in the sub-structure for the bridges pylons to sit on. Aline where the track actually needs to come and cut off the sub-roadbed to match. I was surprised at how close the roughed in sub-roadbed was to the final "cut" (see image below). This was especially since I had made the spot for the bridge before I even had purchased the exact bridge for this span.

I knew that once the bridge track was in, it would be impossible to adjust/change the piers so I painted and weathered them. That was quite an experience since one was the original resin casting and the second one was a plaster cast made from the first. They took both paint and stain differently. It wasn't easy to get them to look alike. The piers are supposedly cut stone. I started with a black wash to get black into the deep cracks. I did a coat of normal latex paint (tan) and then second a wash of black to "highlight" the cracks and crevasses. I then did an almost dry brush of the same tan from the top to highlight the tops exposed to the "sun". The effect was good but too uniform. So I did a second heavy wash of black but only on the bottom and more than just filling in the cracks. This was to simulate much longer periods of time in or very near the water. On the top part I did an upside down dry brush of black to simulate shadows on the bottom. I then did a few "stripes" side to side of dark brown and a lower one of green to simulate the high water marks of "flood" events and the green for mold from being wet all the time. Finally I did a white and purple dry brush from top to bottom (heavier at the top) to highlight the edges of the stones and simulate bleaching from the "hot sun". I neglected to take a photo so I'll post that later.

My birthday, I'm officially an old man now, spent it after work putting in the next section of rail and next section of the back drop. After I got home I worked on the mine building knowing I had to have enough of it done to get the tracks positioned properly.

Dateline April 13 - Friday

Repeat of previous days, next section of track as far as the pins would go, next section of back drop done. Now getting close to the bridges I put in the sub-structure for the bridges pylons to sit on. Aline where the track actually needs to come and cut off the sub-roadbed to match. I was surprised at how close the roughed in sub-roadbed was to the final "cut" (see image below). This was especially since I had made the spot for the bridge before I even had purchased the exact bridge for this span.

I knew that once the bridge track was in, it would be impossible to adjust/change the piers so I painted and weathered them. That was quite an experience since one was the original resin casting and the second one was a plaster cast made from the first. They took both paint and stain differently. It wasn't easy to get them to look alike. The piers are supposedly cut stone. I started with a black wash to get black into the deep cracks. I did a coat of normal latex paint (tan) and then second a wash of black to "highlight" the cracks and crevasses. I then did an almost dry brush of the same tan from the top to highlight the tops exposed to the "sun". The effect was good but too uniform. So I did a second heavy wash of black but only on the bottom and more than just filling in the cracks. This was to simulate much longer periods of time in or very near the water. On the top part I did an upside down dry brush of black to simulate shadows on the bottom. I then did a few "stripes" side to side of dark brown and a lower one of green to simulate the high water marks of "flood" events and the green for mold from being wet all the time. Finally I did a white and purple dry brush from top to bottom (heavier at the top) to highlight the edges of the stones and simulate bleaching from the "hot sun". I neglected to take a photo so I'll post that later.

Amtrakking

Member

Iron horseman.....

Firstly pleasure to reply. I am relatively new on these boards and like to see how others complete their projects. Looks like it is going to be nice.

Amtrakking

Firstly pleasure to reply. I am relatively new on these boards and like to see how others complete their projects. Looks like it is going to be nice.

Amtrakking

There's a pretty decent lumber yard just north of Jewell on Wadsworth (west side): https://www.frlco.com/. Not sure where in Denver you are, and this is obviously too late for your current build, but for future use it might be worth noting.

If you need help with building any of the buildings I'd be happy to lend a hand.

If you need help with building any of the buildings I'd be happy to lend a hand.

Iron Horseman

Well-Known Member

I used to live SW (near Southwest Plaza), but now I am the opposite direction. NE near Eastlake. I'll have to look them up next time, perchance they even carry homasote.There's a pretty decent lumber yard just north of Jewell on Wadsworth (west side): https://www.frlco.com/. Not sure where in Denver you are, and this is obviously too late for your current build, but for future use it might be worth noting.