traingeek344

Member

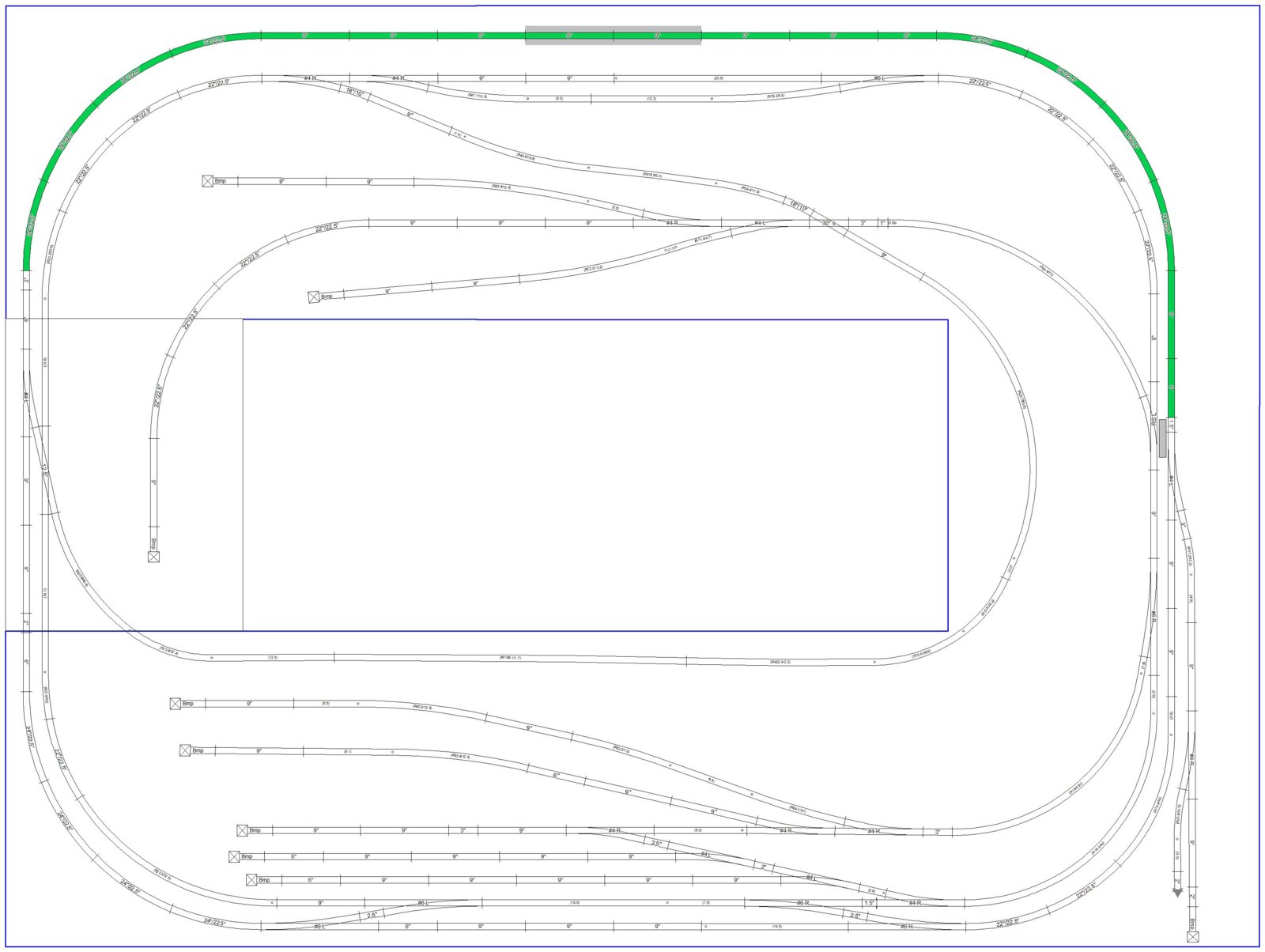

I have designed my track layout using SCARM software. I built the bench work for double continuous run loops, with cross overs. The highlighted track designates raised bed at a 3% grade. The main turnouts are no. 6 and the switching ones are no .4. The minimum radius curves are 22". I do have access to all 4 sides by using a duck under since the bench work top is 42" from the floor, giving me 40" clear access. I designed a small cart with casters to ride on to go underneath since my 70 year old body is not as limber as it used to be.

I have attached my layout for your critique. Please offer any suggestions or corrections where I can improve the flow. I did not design a reversing loop. I'm told I will wish I had one. I'm also unsure if I will be using DC or DCC. I do have about a dozen older engines, some still in boxes, that are DC. The wiring could be quite frightening in DC. Wiring in DCC looks easier, but the expense is much more. All you seasoned modelers, please help.

I have attached my layout for your critique. Please offer any suggestions or corrections where I can improve the flow. I did not design a reversing loop. I'm told I will wish I had one. I'm also unsure if I will be using DC or DCC. I do have about a dozen older engines, some still in boxes, that are DC. The wiring could be quite frightening in DC. Wiring in DCC looks easier, but the expense is much more. All you seasoned modelers, please help.